Rotary Kiln

Product Details:

Rotary Kiln Price And Quantity

- 1 Unit

- 500000000.00 - 800000000.00 INR/Unit

Rotary Kiln Trade Information

- 1-5 Unit Per Month

- 30 Days

Product Description

We have a team of experts to manufacture, supply and export superior quality Rotary Kiln as per set industry standards. This product is made carrying out two processes like endothermic (heat absorbing) or exothermic (heat liberating) methods. In addition to this, precision engineered Rotary Kiln is appropriate for Culmination as well as drawing. In calculaton, materials are heated to the required measure of temperature with chemical as well as physical process. Tyres of the Rotary Kiln is driven by Girth gear. Pinion gear and gear box are major parts of the machine. We manufacture Rotary Kiln in a variety of models, technical specifications and industry standard parameters to suit various applications areas.

Some of the features are:

- Semi-Automatic Custom built design

- Optimized Power Consumption

- Long service life

- Low maintenance cost

- High corrosion resistance

(Capacity 400 TPD To 3000 TPD) ROTARY KILN :

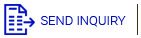

The Rotary Kiln produced using MS Steel Plate, and Lined with firebrick. The Kiln slants somewhat (1-40) and gradually pivots on its hub at somewhere around 30 and 200 cycles for every hour. Rawmix is nourished in at the upper end, and the revolution of furnace reasons it step by step to move and go down to the next end of the oven. At the flip side fuel, is blown in through the burner, delivering a substantial concentric fire in the lower piece of the oven. As material moves under the fire, it achieves its top temperature, before dropping out of the oven into the cooler. Air is drawn first through the cooler and after that through the oven for ignition of the fuel. In the cooler the air is warmed by the cooling clinker so that it might be 350 to 850 0C preceding it enters the furnace, in this way creating extraordinary and fast ignition of the fuel. ovens Rotary run 24 hours a day, and are commonly ceased just for a couple of days a few times every year for fundamental upkeep. This is an imperative control, in light of the fact that warming up and chilling off are long, inefficient and harming procedures. Continuous keeps running the length of year and a half have been accomplished.

Advantages:

- Minimum maintenance

- Easy to work.

- Short Gestation period.

- Better proficiency in force utilization.

- Maximum fuel saving

- Low Installed Cost.

- Trusted and demonstrated inconvenience free innovation.

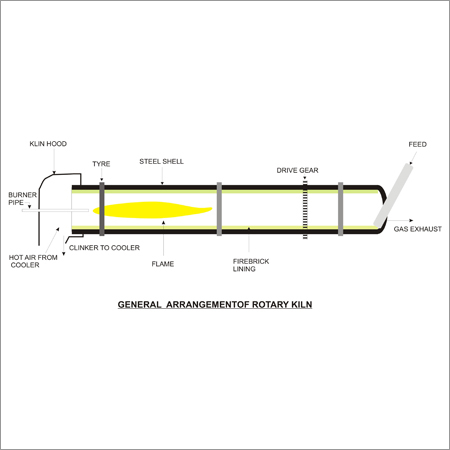

Process of Cement:

- Raw material transportation and Grinding.

- Burning the kiln with Pre heaters and Pre Calcinations.

- Clinker grinding.

- Storage and Packing.

Product details

| Material | Mild Steel |

| Brand | Megatech |

| Firing Method | Direct firing,Indirect firing |

| Pre heaters | Grate,Gas-Suspension |

| Process | Dry |

| Capacity | 400 TPD To 3000 TPD |

Other Products in 'Cement Plants' category

|

MEGATECH INTERNATIONAL PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |